RVCR Specifics

A mechanism of Energy Conversion invloving two bent pistons (sets) ind a toroidal

chamber with a sequential opertion the combines features of positive displacement and rotary mechanisms.

Overview

Machine structure basics

A mechanism of rotating pistons that combines positive displacement and rotary mechnaisms.

When the moving parts are forced, they actuate motion in their connected links. Like in case of flow energy in wind or in water from dams that turn the turbines or electromagnetic in case of motors – they eventually lead to rotation of power generators or wheels. For nearly 100 years now only 2 types of mechanisms are mostly used in Primemovers and utility machines. The ‘Slider-Crank’ used and rotary mechanism. RVCR mechanisms simplifies conversion of energy within fluids into mechanical work (and Vice Versa) whilst enhancing efficiency and miniaturization.

The genesis of RVCR is the invention by Er. Ajee Kamath, which details a new configuration of components of novel geometry, into an assembly of ‘Moving elements’ (ME) and ‘Stationary Elements’ (SE). Improving efficacy of converting fluid forces to torque, is key to RVCR mechanism.

RVCR is a superior alternative to the century old conventional ‘Slider Crank’ and ‘Rotary mechanisms’. It is a new addition in mechanisms that simplifies conversion of energy within fluids into mechanical work (and Vice Versa) that enhances efficiency and miniaturization.

Understanding RVCR

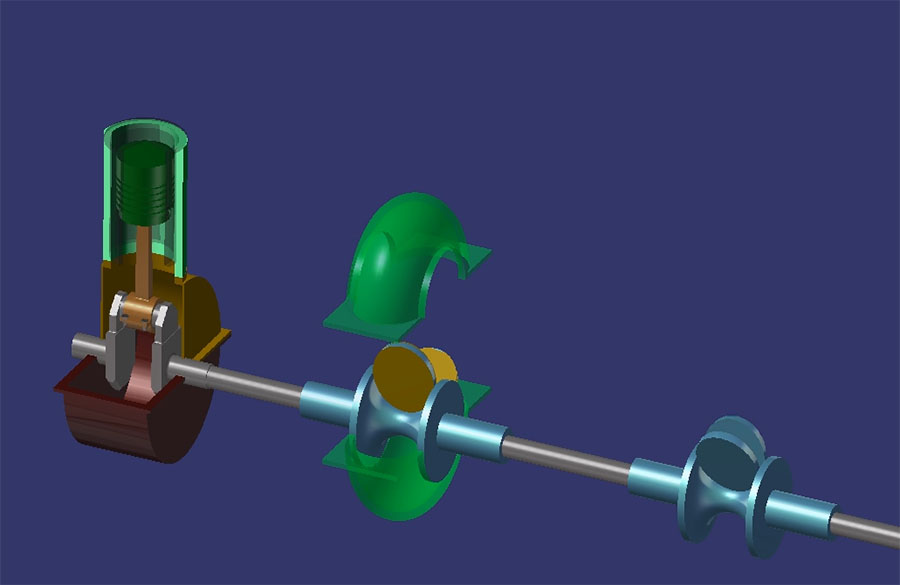

Beginning with conventional slider crank mechanism. It comprises of cylindrical piston sliding inside a Barrel (same as in a syringe used for injections to patients). While one side of the piston draws fluid, the other side is used pull and push it. The needle is fitted on top of syringe, and the fluid is sucked in and pushed out through it. In machines the barrel to is fitted with a covering called head that has valves for allowing the fluid and out of the barrel.

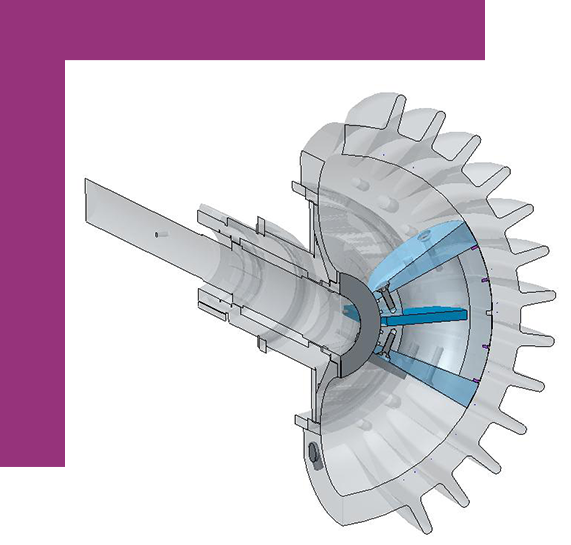

RVCR is about bending the barrel, into a toroid. The pistons are bent and a pair of bent pistons are placed within the toroidal space. When one bent piston slides the other one stays rigidly stationary.

The moving bent piston (referred as piston-vane) now has one side drawing fluid (the side moving away for the stationary vane-piston) while the other side is pushing fluid is against the stationary one. The stationary piston acts as the head. The vane-piston fits closely inside the toroid, and sealing arrangements to ensure the fluids on either side of the vane-piston do not leak past to the other side.

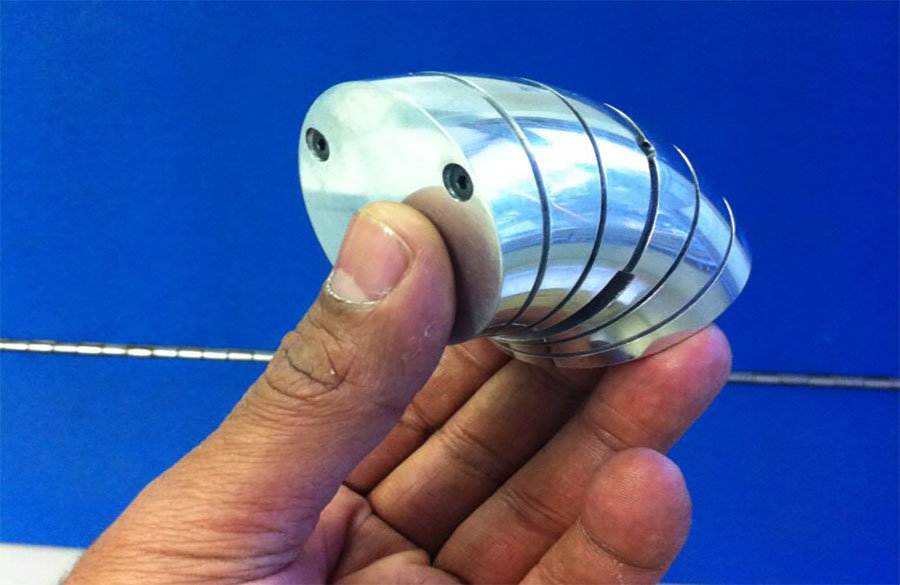

MANUFACTURED-BENT-PISTON

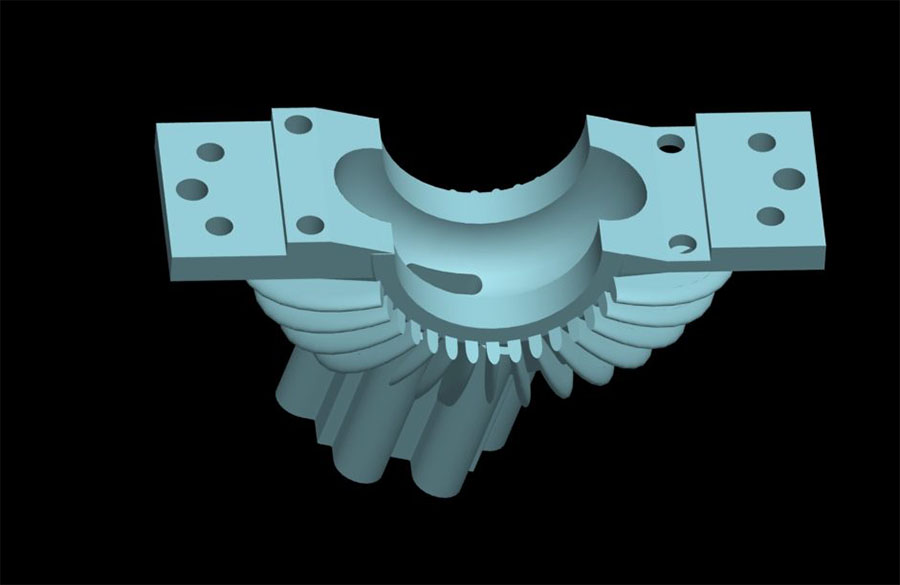

TOROIDAL CASING ONE HALF

PISTON-VANE & SLEEVE ASSEMBLY

Mechanism Comparison on a single shaft

RVCR Design

RVCR system uniqueness

RVCR animations

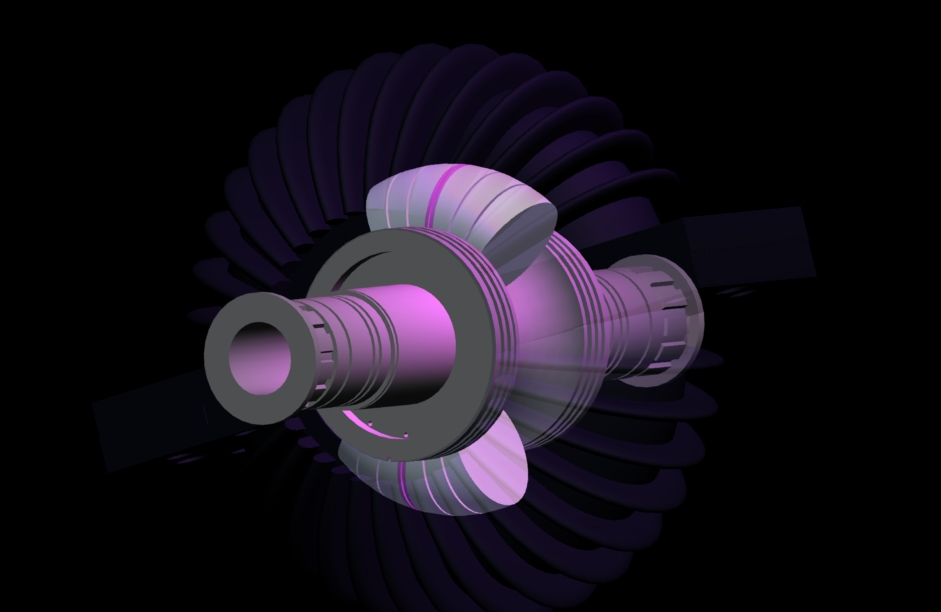

RVCR enables sequential cyclic rotary motion of piston vanes

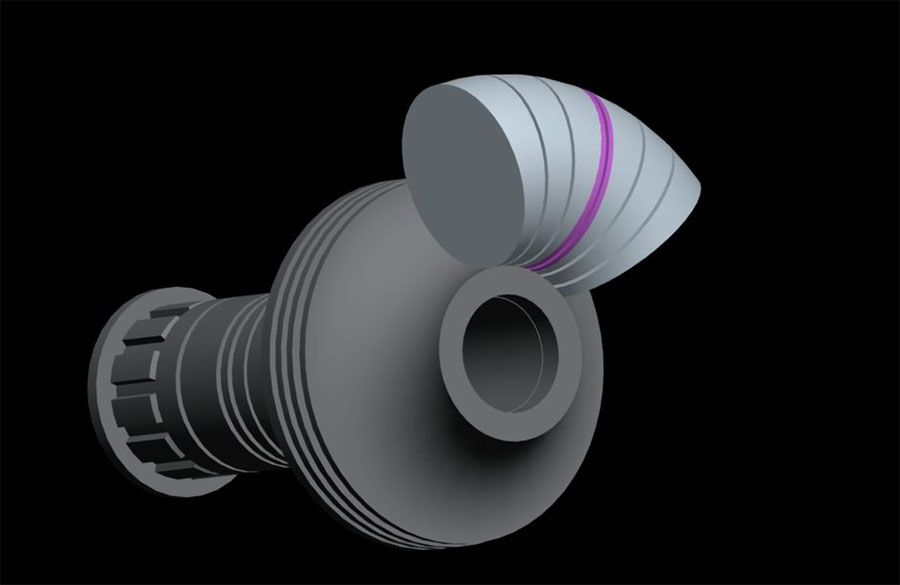

SLEEVE VANE PAIR MOUNTING ON SHAFT

RVCR SLEEVE VANE ANIMATION

RVCR attributes

- Attains Compression/ Expansion thermodynamic) gas processes.

- Achieves controlled variation of angular displacement of rotors.

- Attains analogous Variation in Compression/Expansion Ratios.

- 1st to attain ‘Constant Volume gas process’ between strokes.

- Deploys ‘Opposed Piston’ Principle within One Enclosed Chamber

- Deploys Double acting Piston’ with equal cross sectional areas.

- Packages two independent chains of Rotors in one chamber