RVCR Applications

Green fuel & Renewable energy Prime-movers

Motors and drive systems

Utilities : – Compressors/ Pumps; Hydraulic, Metering and Dosing devices

Overview

RVCR principle opens an entire new dimension in machine systems especially FHM (Fluid Handling Machines). They include Primemovers like engines powering land transport, maritime propulsion, power-generation; Wind and Hydro motors for renewable energy; motors, compressor, variable delivery pumps, metering devices etc.

I.C.Engine Primemover Application

I.C.Engine Primemover Application

RVCR is all about high enhancement in efficiency It attains VCR with easy ease with external controls and hence attaining better combustion control. The combustion of different fuels in an I.C. Engine is one of the most challenging aspects. However, RVCR provides for constant volume which makes large residence time possible for combustion. RVCR Engines shall facilitate green-fuel enforceability without being in conflict with fossil-fuel economic structures, for a greener Industry ecosystem.

RVCR is all about high enhancement in efficiency It attains VCR with easy ease with external controls and hence attaining better combustion control. The combustion of different fuels in an I.C. Engine is one of the most challenging aspects. However, RVCR provides for constant volume which makes large residence time possible for combustion. RVCR Engines shall facilitate green-fuel enforceability without being in conflict with fossil-fuel economic structures, for a greener Industry ecosystem.

The Application Segments

We understand the RVCR technology best and how to customize it into segment specific technologies. The shift in the industry is towards greener options to reduce GHG emissions in engine Exhaust. The trend is in automotive sector is consistently moving towards electrification and hybrids. In the maritime and many land based applications we see the shift if towards clean fuels like LNG, CNG, Biofuels and Hydrogen etc.

RVCR shall facilitate green-fuel enforceability without being in conflict with fossil-fuel economic structures, for a greener Industry ecosystem.

RVCR I.C. Engine project is covered in the dedicated page under the opportunities section.

RVCR shall facilitate green-fuel enforceability without being in conflict with fossil-fuel economic structures, for a greener Industry ecosystem.

RVCR I.C. Engine project is covered in the dedicated page under the opportunities section.

We have prioritized the customization of RVCR knowhow for developing the technology for 450 to 600 Hp applications. This specification is deduced as the MVP ‘minimum viable product’. This is with consideration to the wide range of applications it suffices.

We have prioritized the customization of RVCR knowhow for developing the technology for 450 to 600 Hp applications. This specification is deduced as the MVP ‘minimum viable product’. This is with consideration to the wide range of applications it suffices.

This section contains technical details for those skilled in the art.

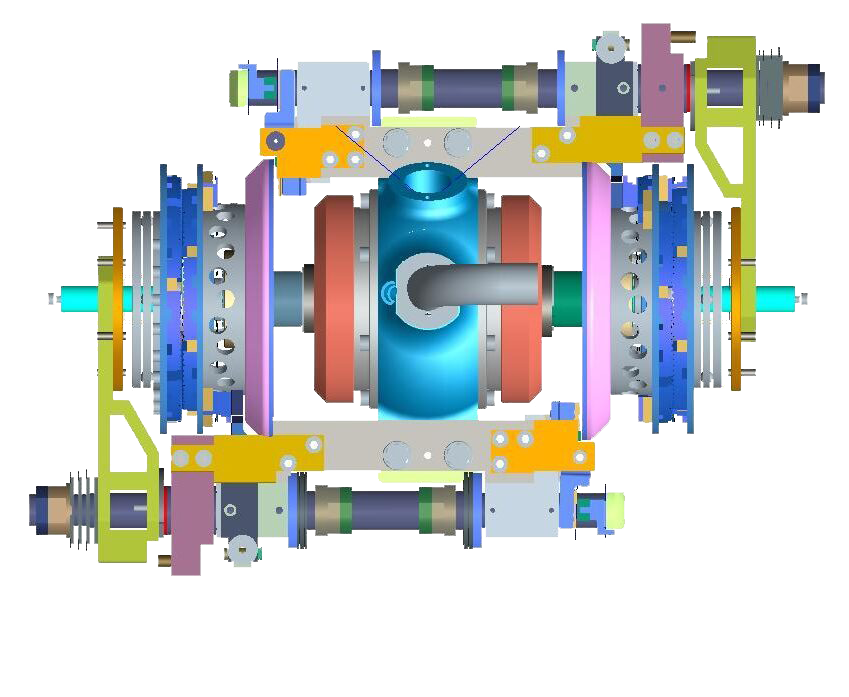

The reduction and increase in volume trapped between the piston vanes is used for compression and expansion. These are the essential thermodynamic gas processes in I.C.Engine. The other two processes are the heat addition and removal. All these processes can be explicitly achieved with RVCR kinematics. The animation depicts the Piston-vane sequence and the gas process. The gas forces are always directly transferred to the central output shaft through the sleeves.

This section contains technical details for those skilled in the art.

The reduction and increase in volume trapped between the piston vanes is used for compression and expansion. These are the essential thermodynamic gas processes in I.C.Engine. The other two processes are the heat addition and removal. All these processes can be explicitly achieved with RVCR kinematics. The animation depicts the Piston-vane sequence and the gas process. The gas forces are always directly transferred to the central output shaft through the sleeves.

RVCR combines the efficiency gains from ‘Positive Displacement’ and the Compactness of the rotary Mechanism. This new methodology is capable of delivering many new features and functionalities. The most important of them is VCR ‘Variable Compression Ratio’. VCR feature has been pursued for almost a 100 years by almost every global major, but it has remained elusive. VCR is key to gaining quantum leap in efficiency and multi-fuel adaptability (real-time switching from fossil to green-fuels).

RVCR combines the efficiency gains from ‘Positive Displacement’ and the Compactness of the rotary Mechanism. This new methodology is capable of delivering many new features and functionalities. The most important of them is VCR ‘Variable Compression Ratio’. VCR feature has been pursued for almost a 100 years by almost every global major, but it has remained elusive. VCR is key to gaining quantum leap in efficiency and multi-fuel adaptability (real-time switching from fossil to green-fuels).

Process depiction

This CAD model animation depicts operation of exhaust valve, its drive chain and fuel injection.

The RVCR concept-based engine was conceived, and its technology knowhow is developed. The sequential motion of piston requisite for Gas Processes in I.C. Engines is achieved in a smarter, compacter way with piston-vane pair. While one piston-vane set is rotating, it’s counterpart performs the equivalent of an Cylinder head.

The conventional reciprocating motion of cylindrical piston is a source of major limitations and RVCR eliminates it. The RVCR piston-vane is radially fitted on the sleeve and eliminates linear reciprocating motion. The connecting rod, top end bearing (Gudgeon pin) and bottom end bearings are not present.

Salient attributes

- thermodynamic prosses called Constant Volume Heat exchange (CVHE);

- Direct torque transfer through the entire expansion process.

- Real time wide range Variable compression ratio (VRC).

- Multi fuel flexibility (Switching of fuels during operation).

- uniform peak efficiency under all load conditions

- Miniaturization by warping of gas volume around shaft; Reduced operations costs by minimizing of component wear. Etc.

The Implications

Renewable energy motors

Tapping of renewable wind energy leads to only one picture – The 3-blade wind turbine. Same is the case with hydro-energy where we see Kaplan and Francis turbines. There are many more vertical turbine types.

Tapping of renewable wind energy leads to only one picture – The 3-blade wind turbine. Same is the case with hydro-energy where we see Kaplan and Francis turbines. There are many more vertical turbine types.

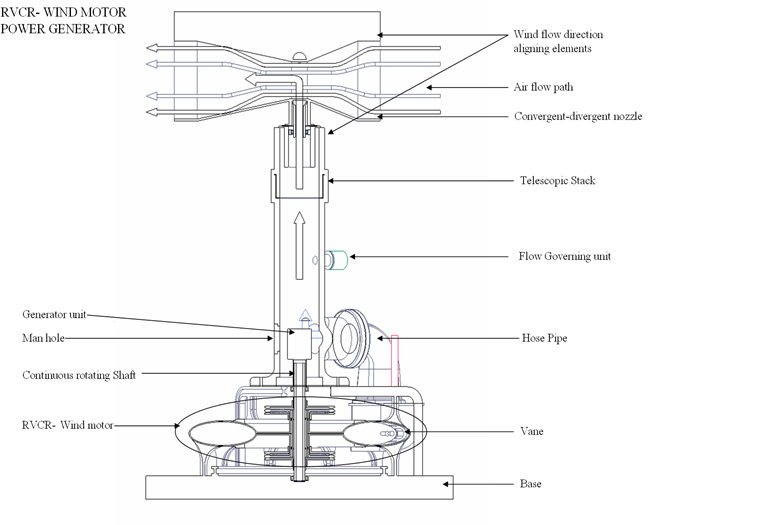

We introduce a new concept of utilizing Positive displacement mechanism for making next generation High efficiency wind motors. the methodology applied is about Converting flow energy in wind/hydro (Rivers, tidal) to pressure differential for driving RVCR +ve displacement motors

We introduce a new concept of utilizing Positive displacement mechanism for making next generation High efficiency wind motors. the methodology applied is about Converting flow energy in wind/hydro (Rivers, tidal) to pressure differential for driving RVCR +ve displacement motors

Turbine vs RVCR tech overview

The section contains technical details for those skilled in the art.

The axial flow FLUID turbines are rotary machines converting Wind energy into Power. The root principal differentiator between rotary and RVCR methods is in the wind force tapping method. Conventional wind turbines are driven by lift, achieved by aerofoiled profile of turbine blades. RVCR uses pressure differential between high wind velocity zone and ground level stagnant air conditions.

RVCR is the 1st in basing a FLUID motor on a rotary positive displacement mechanism. The RVCR system deploys a Convergent divergent nozzle in the flow path of air rather than a turbine. This creates low pressure at throat of the Nozzle. An air stack connects the low pressure at nozzle throat to the RVCR wind motor exhaust.

The high pressure at lower altitude region is connected to the intake side. The air flow induced from the high to low pressure point passes through the wind motor by turning the piston vanes which seal any air leak past its sides. This methodology cannot be deployed in turbines for air slip between blades. Even placing reaction turbines with closely packed blades has issues with air varying differential pressures and flow . The complexities of conventional positive displacement system make it difficult.

Superior attributes

RVCR wind motors can be installed at ground level as it is easy to communicate the air pressure differential without losses. evaluated in terms of its implication on increment in efficiency of Power take-off, indicates towards the gain in Value. The simplified geometry of the technology component systems when compared to conventional turbines complements further gains in value

RVCR enables multi-fold increase in energy capture efficiency compared to modern wind turbines. The RVCR principal simplifies the mechanics of Prime-Mover to reduce the Capital Cost drastically and the engineering involved reduces operations cost.

RVCR wind motors can be installed at ground level as it is easy to communicate the air pressure differential without losses. evaluated in terms of its implication on increment in efficiency of Power take-off, indicates towards the gain in Value. The simplified geometry of the technology component systems when compared to conventional turbines complements further gains in value

RVCR enables multi-fold increase in energy capture efficiency compared to modern wind turbines. The RVCR principal simplifies the mechanics of Prime-Mover to reduce the Capital Cost drastically and the engineering involved reduces operations cost.

The Topic is covered on the RVCR wind project page.

The Topic is covered on the RVCR wind project page.

Summary

The entire range of applications of RVCR is an exhaustive list and covers almost every fluid handling machine based on conventional kinematic mechanisms.