How RVCR works?

Overview

The rotating piston-vanes inside the toroidal casing is is not allowed to collide with the stationary piston-vanes. As the rotating piston approaches a set distance (angle) from the stationary one, the latter one is released and allowed to rotate along with rotating piston synchronously and subsequently the approaching piston is stopped and held stationary It works in the same fashion as the shuttle valve used in the invention of steam engine by James watt. The moving piston triggers an action ahead of it before reaching its end point in travel.

Rotor sequence control

Handling fluids

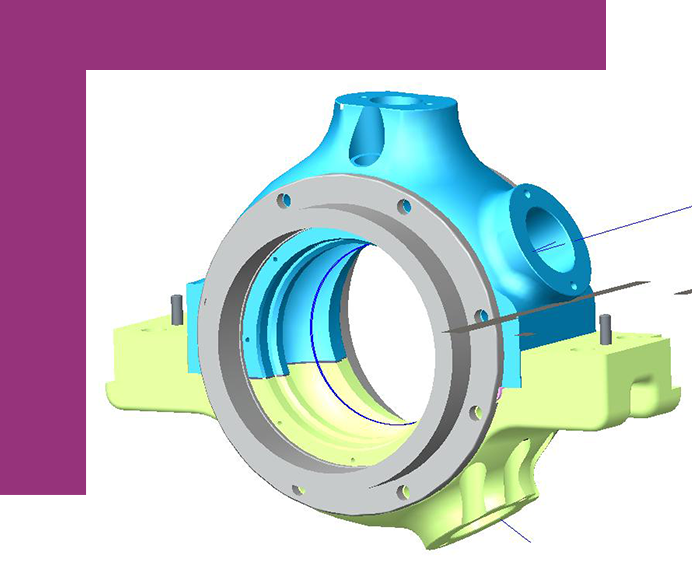

The RVCR is about the volume inside a toroidal casing which is parted by the Piston Vanes. The volume trapped between the piston vanes is the fluid area. As the piston-vane rotates inside the toroidal chamber the volume between the Piston-Vanes changes. The volume ahead of the piston-vane reduces and behind it increases.

The rotating piston-vane compresses air ahead of it, against the stationary Piston-vane. The increasing volume behind it rarifies the air. The fluids spaces communicate with the outside air through conventional valves and ports. Valves are operated in relation to piston-vane position by cams mounted on sleeves and its associated drive chain. The choice of ports and valve are made to suit the application.

This sequential gas volume change across the rotating piston-vane during operation is used for the various thermodynamic processes. Insert cut section animation.

The RVCR is about the volume inside a toroidal casing which is parted by the Piston Vanes. The volume trapped between the piston vanes is the fluid area. As the piston-vane rotates inside the toroidal chamber the volume between the Piston-Vanes changes. The volume ahead of the piston-vane reduces and behind it increases.

The RVCR is about the volume inside a toroidal casing which is parted by the Piston Vanes. The volume trapped between the piston vanes is the fluid area. As the piston-vane rotates inside the toroidal chamber the volume between the Piston-Vanes changes. The volume ahead of the piston-vane reduces and behind it increases.

The rotating piston-vane compresses air ahead of it, against the stationary Piston-vane. The increasing volume behind it rarifies the air. The fluids spaces communicate with the outside air through conventional valves and ports. Valves are operated in relation to piston-vane position by cams mounted on sleeves and its associated drive chain. The choice of ports and valve are made to suit the application.

This sequential gas volume change across the rotating piston-vane during operation is used for the various thermodynamic processes. Insert cut section animation.

The rotating piston-vane compresses air ahead of it, against the stationary Piston-vane. The increasing volume behind it rarifies the air. The fluids spaces communicate with the outside air through conventional valves and ports. Valves are operated in relation to piston-vane position by cams mounted on sleeves and its associated drive chain. The choice of ports and valve are made to suit the application.

This sequential gas volume change across the rotating piston-vane during operation is used for the various thermodynamic processes. Insert cut section animation.

Variable compression

In thermodynamics this lowering of volume converts to higher pressure. The varying of the point of actuation varies the volume reduction ahead of piston-Vane. This translates to varying of compression ratio and hence the pressure ratios.

RVCR allows real-time varying of the said point of actuation of synchronous rotation of piston-vane with ease. This is done by manipulating follower position along varying cam dwell angle.

The volume sandwiched between the two piston vanes remains constant during synchronous rotation. In thermodynamic terms this translates to ‘Constant Volume Process’. Insert now ppts slide on VCR

In thermodynamics this lowering of volume converts to higher pressure. The varying of the point of actuation varies the volume reduction ahead of piston-Vane. This translates to varying of compression ratio and hence the pressure ratios.

RVCR allows real-time varying of the said point of actuation of synchronous rotation of piston-vane with ease. This is done by manipulating follower position along varying cam dwell angle.

The volume sandwiched between the two piston vanes remains constant during synchronous rotation. In thermodynamic terms this translates to ‘Constant Volume Process’. Insert now ppts slide on VCR