What is RVCR

A breakthrough in machine heart tech

For 150 years machines catered to our transport and power needs, but little do many know of Primemovers – the heart of machines.

Like our heart has various muscles and valves, primemovers have links. RVCR is a new science of primemovers

To pump blood through our body for powering it

Primemovers like engines, turbines and motors powered us into mechanized age. Today they are the polluters. We have developed RVCR technology- that delivers tomorrow’s green primemovers.

RVCR specifics

A new configuration of rotary piston mechanics.

Almost all machines today are based on either the ‘Slider-Crank’ or the ‘Rotary’ mechanism (known as kinematic mechanisms).

The genesis of RVCR is novel component geometries and its configuration that simplifies conversion of energy within fluids like fuel or wind etc., into power. Fluids actuate motion of links which eventually rotate wheels or power generators. Key to RVCR is enhancing of efficacy of this energy conversion.

How RVCR works

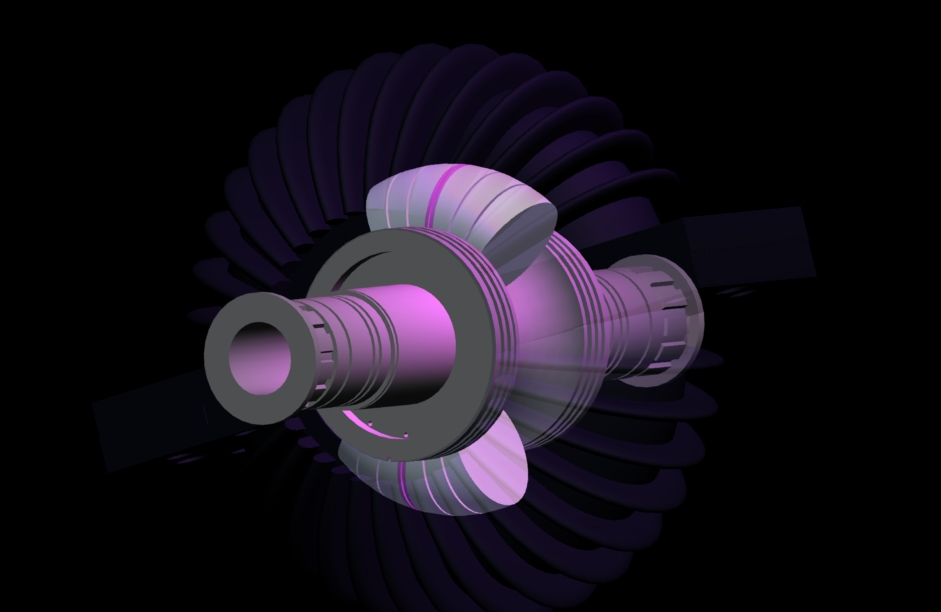

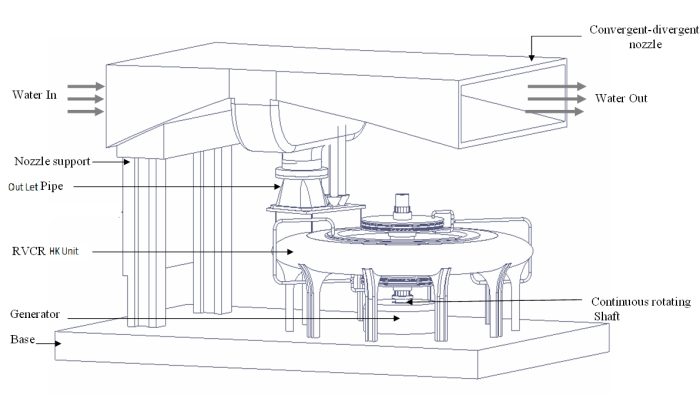

Perceive - Rotating curved piston with cam actuated shuttle valve

Simply speaking there are two rotors on a single shaft wherein One rotor decouples and becomes a stator, while the other turns. They switch roles alternately as rotor and stator. Like in a steam engine the piston actuates a shuttle valve before it reaches the end position to allow reversing stem flow, RVCR rotary piston actuate adjacent rotor as it nears the end of its turning span. This is crux of RVCR RVCR’s new mechanism is that it eliminates the need of dedicated stationary link, by dynamic reorienting of a twin Rotor system, enabling a new physics of energy conversion.

RVCR kinematics applies to all Fluid Handling machines RVCR kinematics is a replacement for both positive displacement (Reciprocatory & rotary) and rotary centrifugal kinematic system. The Variable displacement characteristic adds to the versatility of the mechanism. The component elements and their parameters can be customized for both high pressure and high-volume applications. The tangential piston force dynamics can be adapted to cover both +ve displacement and the rotary centrifugal applications. The RVCR product projects are covered separately.

RVCR feasibility

Solving rotary system faults

RVCR overcomes issues with sealing and inertia common in rotary kinematic systems. Unlike previous Wankel system RVCR has no (straight-line edge or large-flat-side surfaces) sealing issues, RVCR employs a combination of tangential spring force and labyrinth sealing methodology for across rotary piston vane sealing and side-sealing respectively.

RVCR allows large rapid expansion at low speeds hence solving inertia issues are ,. The alternate Stopping and Starting of RVCR rotors is made easy by slower speeds and by cushioning of rotors by gas forces.

RVCR viability

Viable green transition

RVCR most advanced competitive Zero-Carbon Technologies

RVCR is about enhancing efficacy of force and energy transfer. Furthermore, easy, and dynamic control over change of volume and the rate of change of volume allows newer ways in improving thermodynamic gas processes. Comparing capital cost components of total material, manufacture cost, and system’s needs, RVCR stands economical than all conventional Primemovers.

RVCR operational costs reduces from lesser strenuous operations demand, coupled with leap in efficiency and never before capabilities form VCR attributes. Slower speeds reduces frictional losses improving energy efficiency.

RVCR value

Cost effective climate regulation compliance

RVCR technology products derive value for its inherent attributes.

RVCR is a simplified system to combine features like double acting and opposed piston, making it a highly efficient, compact, and has low carbon footprint. It combines the system efficiency of ‘Positive Displacement Mechanism’, fine ‘VCR’ control, and gains from ‘Direct Torque Transfer’ characteristics of Rotary mechanism, into one highly advanced primemover tech.

It opens long-standing theoretical ceiling limits in machine energy conversion efficiencies and performance capabilities.

Broader impact

Redefining - climate recovery response

Enabling an comprehensive alternate industrial strategy for Climate Change Mitigation to fix global warming.

RVCR ensures Unhooking from fossil fuel dependency. It enables a smooth transition to green fuel in the heavy transport sector. In doing so RVCR carves newer markets of green fuels. The onset of RVCR leads to lowering of Levelized cost of power from renewable energy.

RVCR seeds an entire breed on next gen green machines and stands as a unified solution to shape the 21st century green industry ecosystem.

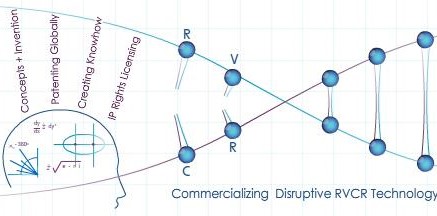

Our R&D

R&D on newer “Zero Carbon” technologies

We conduct research, and development of to create newer seed technologies based on the breakthrough RVCR concept. We then design new breed of primemovers, and systems based on the developed technology capable of outperforming future climate regulations of transport and energy industry.

We generate global IP of products based on the developed RVCR technologies

Contact us

We operate from our base in UK and India. For more information, please drop us a mail or use the form.